400G transceivers and cables play a vital role in the process of constructing a 400G network system. Then, what is a 400G transceiver? What are the applications of QSFP-DD cables? Find answers here.

FAQs on 400G Transceivers and Cables Definition and Types

Q1: What is a 400G transceiver?

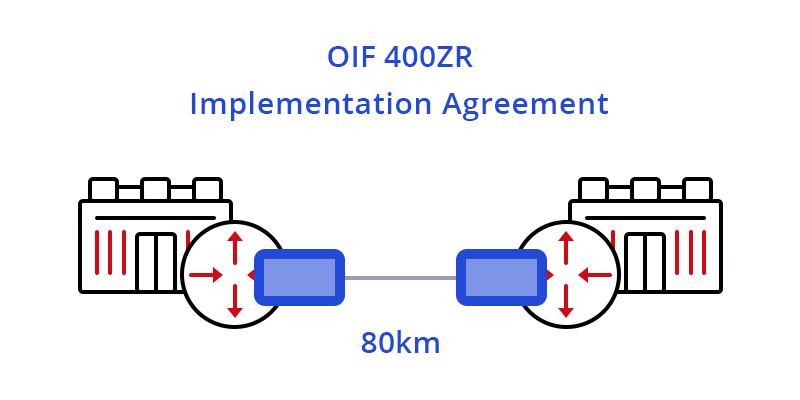

A1: 400G transceivers are optical modules that are mainly used for photoelectric conversion with a transmission rate of 400Gbps. 400G transceivers can be classified into two categories according to the applications: client-side transceivers for interconnections between the metro networks and the optical backbone, and line-side transceivers for transmission distances of 80km or even longer.

Q2: What are QSFP-DD cables?

A2: QSFP-DD cables contain two forms: one is a form of high-speed cable with QSFP-DD connectors on either end, transmitting and receiving 400Gbps data over a thin twinax cable or a fiber optic cable, and the other is a form of breakout cable that can split one 400G signal into 2x 200G, 4x 100G, or 8x 50G, enabling interconnection within a rack or between adjacent racks.

Q3: What are the 400G transceivers packaging forms?

A3: There are mainly the following six packaging forms of 400G optical modules:

- QSFP-DD: 400G QSFP-DD (Quad Small Form Factor Pluggable-Double Density) is an expansion of QSFP, adding one row to the original 4-channel interface to 8 channels, running at 50Gb/s each, for a total bandwidth of 400Gb/s.

- OSFP: OSFP (Octal Small Formfactor Pluggable, Octal means 8) is a new interface standard and is not compatible with the existing photoelectric interface. The size of 400G OSFP modules is slightly larger than that of 400G QSFP-DD.

- CFP8: CFP8 is an expansion of CFP4, with 8 channels and a correspondingly larger size.

- COBO: COBO (Consortium for On-Board Optics) means that all optical components are placed on the PCB. COBO is with good heat-dissipation and small-size. However, since it is not hot-swappable, once a module fails, it will be troublesome to repair.

- CWDM8: CWDM 8 is an extension of CWDM4 with four new center wavelengths (1351/1371/1391/1411 nm). The wavelength range becomes wider and the number of lasers is doubled.

- CDFP: CDFP was born earlier, and there are three editions of the specification. CD stands for 400 (Roman numerals). With 16 channels, the size of CDFP is relatively large.

Q4: What 400G transceivers and QSFP-DD cables are available on the market?

A4: The two tables below show the main types of 400G transceivers and cables on the market:

| 400G Transceivers | Standards | Max Cable Distance | Connector | Media | Temperature Range |

|---|---|---|---|---|---|

| 400G QSFP-DD SR8 | QSFP-DD MSA Compliant | 70m OM3/100m OM4 | MTP/MPO-16 | MMF | 0 to 70°C |

| 400G QSFP-DD DR4 | QSFP-DD MSA, IEEE 802.3bs | 500m | MTP/MPO-12 | SMF | 0 to 70°C |

| 400G QSFP-DD XDR4/DR4+ | QSFP-DD MSA | 2km | MTP/MPO-12 | SMF | 0 to 70°C |

| 400G QSFP-DD FR4 | QSFP-DD MSA | 2km | LC Duplex | SMF | 0 to 70°C |

| 400G QSFP-DD 2FR4 | QSFP-DD MSA, IEEE 802.3bs | 2km | CS | SMF | 0 to 70°C |

| 400G QSFP-DD LR4 | QSFP-DD MSA Compliant | 10km | LC Duplex | SMF | 0 to 70°C |

| 400G QSFP-DD LR8 | QSFP-DD MSA Compliant | 10km | LC Duplex | SMF | 0 to 70°C |

| 400G QSFP-DD ER8 | QSFP-DD MSA Compliant | 40km | LC Duplex | SMF | 0 to 70°C |

| 400G OSFP SR8 | IEEE P802.3cm; IEEE 802.3cd | 100m | MTP/MPO-16 | MMF | 0 to 70°C |

| 400G OSFP DR4 | IEEE 802.3bs | 500m | MTP/MPO-12 | SMF | 0 to 70°C |

| 4000G OSFP XDR4/DR4+ | / | 2km | MTP/MPO-12 | SMF | 0 to 70°C |

| 400G OSFP FR4 | 100G lambda MSA | 2km | LC Duplex | SMF | 0 to 70°C |

| 400G OSFP 2FR4 | IEEE 802.3bs | 2km | CS | SMF | 0 to 70°C |

| 400G OSFP LR4 | 100G lambda MSA | 10km | LC Duplex | SMF | 0 to 70°C |

| QSFP-DD Cables | Catagory | Product Description | Reach | Temperature Range | Power Consumption |

|---|---|---|---|---|---|

| 400G QSFP-DD DAC | QSFP-DD to QSFP-DD DAC | with each 400G QSFP-DD using 8x 50G PAM4 electrical lanes | no more than 3m | 0 to 70°C | <1.5W |

| 400G QSFP-DD Breakout DAC | QSFP-DD to 2x 200G QSFP56 DAC | with each 200G QSFP56 using 4x 50G PAM4 electrical lanes | no more than 3m | 0 to 70°C | <0.1W |

| QSFP-DD to 4x 100G QSFPs DAC | with each 100G QSFPs using 2x 50G PAM4 electrical lanes | no more than 3m | 0 to 70°C | <0.1W | |

| QSFP-DD to 8x 50G SFP56 DAC | with each 50G SFP56 using 1x 50G PAM4 electrical lane | no more than 3m | 0 to 80°C | <0.1W | |

| 400G QSFP-DD AOC | QSFP-DD to QSFP-DD AOC | with each 400G QSFP-DD using 8x 50G PAM4 electrical lanes | 70m (OM3) or 100m (OM4) | 0 to 70°C | <10W |

| 400G QSFP-DD Breakout AOC | QSFP-DD to 2x 200G QSFP56 AOC | with each 200G QSFP56 using 4X 50G PAM4 electrical lane | 70m (OM3) or 100m (OM4) | 0 to 70°C | / |

| QSFP-DD to 8x 50G SFP56 AOC | with each 50G SFP56 using 1x 50G PAM4 electrical lane | 70m (OM3) or 100m (OM4) | 0 to 70°C | / | |

| 400G OSFP DAC | OSFP to OSFP DAC | with each 400G OSFP using 8x 50G PAM4 electrical lanes | no more than 3m | 0 to 70°C | <0.5W |

| 400G OSFP Breakout DAC | OSFP to 2x 200G QSFP56 DAC | with each 200G QSFP56 using 4x 50G PAM4 electrical lanes | no more than 3m | 0 to 70°C | / |

| OSFP to 4x100G QSFPs DAC | with each 100G QSFPs using 2x 50G PAM4 electrical lanes | no more than 3m | 0 to 70°C | / | |

| OSFP to 8x 50G SFP56 DAC | with each 50G SFP56 using 1x 50G PAM4 electrical lane | no more than 3m | / | / | |

| 400G OSFP AOC | OSFP to OSFP AOC | with each 400G OSFP using 8x 50G PAM4 electrical lanes | 70m (OM3) or 100m (OM4) | 0 to 70°C | <9.5W |

Q5: What do the suffixes “SR8, DR4 / XDR4, FR4 / LR4 and 2FR4” mean in 400G transceivers?

A5: The letters refer to reach, and the number refers to the number of optical channels:

- SR8: SR refers to 100m over MMF. Each of the 8 optical channels from an SR8 module is carried on separate fibers, resulting in a total of 16 fibers (8 Tx and 8 Rx).

- DR4 / XDR4: DR / XDR refer to 500m / 2km over SMF. Each of the 4 optical channels is carried on separate fibers, resulting in a total of 4 pairs of fibers.

- FR4 / LR4: FR4 / LR4 refer to 2km / 10km over SMF. All 4 optical channels from an FR4 / LR4 are multiplexed onto one fiber pair, resulting in a total of 2 fibers (1 Tx and 1 Rx).

- 2FR4: 2FR4 refers to 2 x 200G-FR4 links with 2km over SMF. Each of the 200G FR4 links has 4 optical channels, multiplexed onto one fiber pair (1 Tx and 1 Rx per 200G link). A 2FR4 has 2 of these links, resulting in a total of 4 fibers, and a total of 8 optical channels.

FAQs on 400G Transceivers and Cables Applications

Q1: What are the benefits of moving to 400G technology?

A1: 400G technology can increase the throughput of data and maximize the bandwidth and port density of the data centers. With only 1/4 the number of optical fiber links, connectors, and patch panels when using 100G platforms for the same aggregate bandwidth, 400G optics can also reduce operating expenses. With these benefits, 400G transceivers and QSFP-DD cables can provide ideal solutions for data centers and high-performance computing environments.

Q2: What are the applications of QSFP-DD cables?

A2: QSFP-DD cables are mainly used for short-distance 400G Ethernet connectivity in the data centers, and 400G to 2x 200G / 4x 100G / 8x 50G Ethernet applications.

Q3: 400G QSFP-DD vs 400G OSFP/CFP8: What are the differences?

A3: The table below includes detailed comparisons for the three main form factors of 400G transceivers.

| 400G Transceiver | 400G QSFP-DD | 400G OSFP | CFP8 |

|---|---|---|---|

| Application Scenario | Data center | Data center & telecom | Telecom |

| Size | 18.35mm× 89.4mm× 8.5mm | 22.58mm× 107.8mm× 13mm | 40mm× 102mm× 9.5mm |

| Max Power Consumption | 12W | 15W | 24W |

| Backward Compatibility with QSFP28 | Yes | Through adapter | No |

| Electrical signaling (Gbps) | 8× 50G | ||

| Switch Port Density (1RU) | 36 | 36 | 16 |

| Media Type | MMF & SMF | ||

| Hot Pluggable | Yes | ||

| Thermal Management | Indirect | Direct | Indirect |

| Support 800G | No | Yes | No |

For more details about the differences, please refer to the blog: Differences Between QSFP-DD and QSFP+/QSFP28/QSFP56/OSFP/CFP8/COBO

Q4: What does it mean when an electrical or optical channel is PAM4 or NRZ in 400G transceivers?

A4: NRZ is a modulation technique that has two voltage levels to represent logic 0 and logic 1. PAM4 uses four voltage levels to represent four combinations of two bits logic-11, 10, 01, and 00. PAM4 signal can transmit twice faster than the traditional NRZ signal.

When a signal is referred to as “25G NRZ”, it means the signal is carrying data at 25 Gbps with NRZ modulation. When a signal is referred to as “50G PAM4”, or “100G PAM4”, it means the signal is carrying data at 50 Gbps, or 100 Gbps, respectively, using PAM4 modulation. The electrical connector interface of 400G transceivers is always 8x 50Gb/s PAM4 (for a total of 400Gb/s).

FAQs on Using 400G Transceivers and Cables in Data Centers

Q1: Can I plug an OSFP module into a 400G QSFP-DD port, or a QSFP-DD module into an OSFP port?

A1: No. OSFP and QSFP-DD are two physically distinct form factors. If you have an OSFP system, then 400G OSFP optics must be used. If you have a QSFP-DD system, then 400G QSFP-DD optics must be used.

Q2: Can a QSFP module be plugged into a 400G QSFP-DD port?

A2: Yes. A QSFP (40G or 100G) module can be inserted into a QSFP-DD port as QSFP-DD is backward compatible with QSFP modules. When using a QSFP module in a 400G QSFP-DD port, the QSFP-DD port must be configured for a data rate of 100G (or 40G).

Q3: Is it possible with a 400G OSFP on one end of a 400G link, and a 400G QSFP-DD on the other end?

A3: Yes. OSFP and QSFP-DD describe the physical form factors of the modules. As long as the Ethernet media types are the same (i.e. both ends of the link are 400G-DR4, or 400G-FR4 etc.), 400G OSFP and 400G QSFP-DD modules will interoperate with each other.

Q4: How can I break out a 400G port and connect to 100G QSFP ports on existing platforms?

A4: There are several ways to break out a 400G port to 100G QSFP ports:

- QSFP-DD-DR4 to 4x 100G-QSFP-DR over 500m SMF

- QSFP-DD-XDR4 to 4x 100G-QSFP-FR over 2km SMF

- QSFP-DD-LR4 to 4x 100G-QSFP-LR over 10km SMF

- OSFP-400G-2FR4 to 2x QSFP-100G-CWDM4 over 2km SMF

Apart from the 400G transceivers mentioned above, 400G to 4x 100G breakout cables can also be used.

Article Source: FAQs on 400G Transceivers and Cables

Related Articles: